Metrology infrastructure basics

A national measurement infrastructure is a key part of the Quality Infrastructure. Its focus is on providing consumers, businesses and governments with confidence in measurements, for example for regulation, trade, scientific and technological innovation, manufacturing, etc. It does this by ensuring that measurements are "fit-for-purpose" or good enough to do the job.

Metrology (the science of measurement) and traceability of measurement underpin advances in science and technology, industrial innovation, trade and commerce and consumer protection. An effective national measurement system provides modern economies with essential framework to ensure their measurements are accurate and reliable.

Metrology provides the technical basis for the development of documentary standards and a sound national measurement system enables confidence in conformity assessment activities such as calibration services, testing and accreditation in both the regulatory and the voluntary sectors.

This work is supported by legislation or regulation, as part of an economy’s ‘legal metrology system’.

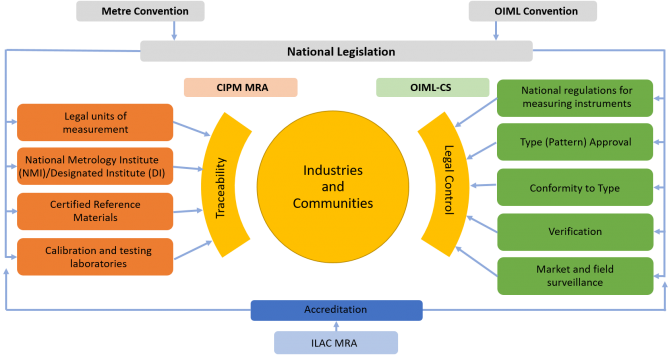

The metrological infrastructure’s many activities can be split into two types of key activities:

- Providing traceability to the International System of Units (SI) – including legal measurement units, the peak measurement standards maintained by the National Metrology Institute are traceable to the SI and ensure that traceability is disseminated to reference laboratories, certification, calibration and testing laboratories

- Establishing legal control - including national regulations for measuring instruments, approval for trade, conformity, verification, market and field surveillance.

Traceability

The International Vocabulary of Metrology – Basic and General Concepts and Associated Terms (VIM 3rd edition) defines traceability as:

"The property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty."

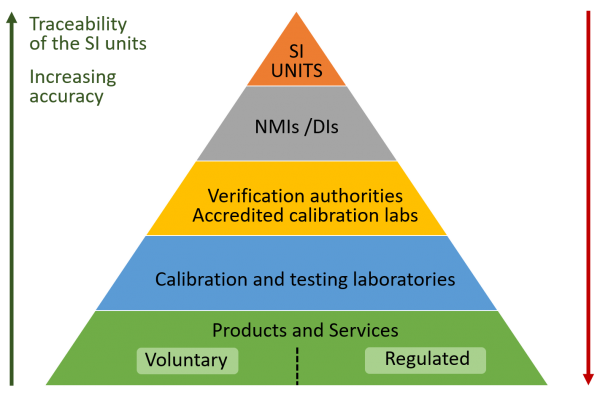

The chain of traceability ultimately leads to the realisations of the International System of Units (SI). This image shows the hierarchy for how measurement standards are disseminated in an economy from the SI.

Legal units of measurement

Every economy needs to set national legal units of measurement based on the SI. To realise the national legal units of measurement, each economy sets primary and other measurement standards. Some economies legislate to recognise overseas standards of measurement to provide legal traceability for some of their national legal units of measurement.

To realise the national legal units of measurement, each economy sets primary and other measurement standards. Some economies need to legislate to recognise overseas standards of measurement to provide legal traceability for some of their national legal units of measurement.

The national metrology institute (NMI) and its designated institutes (DIs) maintain primary, and secondary measurement standards, and provide calibrations and reference materials at appropriate levels of uncertainty (accuracy) for calibration and testing laboratories.

National Metrology Institutes (NMIs)/Designated Institutes (DIs)

According to the Mutual Recognition Arrangement of the International Committee for Weights and Measures (CIPM MRA), the term “National Metrology Institute” (NMI) is defined as:

“The metrology institute designated by the appropriate national governmental or other official authority as that responsible for national measurement standards”

The NMI has the responsibility for developing and maintaining national measurement standards and disseminating the SI units. In many economies, the NMI shares responsibility with one or more Designated Institutes (DIs), which, like the NMI, operate at the peak of the national measurement system. More information about the NMI responsibility or framework can be found on the BIPM website.

Calibration and testing laboratories

Calibration and testing laboratories in turn provide lower accuracy calibrations and measurements to industry and the community.

In the case of mass, the key physical characteristics and metrological requirements used are:

- for the verification of weighing instruments;

- for the verification of weights of a lower class of accuracy; and

- with weighing instruments.

For voluntary standards, calibration and testing laboratories provide traceability services to industry and the community. Calibration certificates for voluntary standards should include the valid period of the calibration under normal conditions of use.

For mandatory standards, calibration laboratories are usually referred to as verifying authorities. They issue verification certificates that convert measurement results into evidence that would be accepted into a court of law without the need to be supported by a string of expert witnesses. This reduces the cost of having to provide measurement evidence.

Certified Reference Materials

Certified Reference Materials (CRMs) are used to support measurements related to chemical composition, biological, clinical, physical and engineering properties and other miscellaneous areas. Reference materials may include pure substances, standard solutions, matrix reference materials, physico-chemical reference materials and reference objects or artefacts. A CRM is defined in the International Vocubulary of Metrology (VIM-3) as:

a "reference material accompanied by documentation issued by an authoritative body and providing one or more specified property values with associated uncertainties and traceabilities, using valid procedures".

Legal control

National regulations for measuring instruments

The International Organisation for Legal Metrology (OIML) has developed measurement regulations for economies need to prescribe. These include:

- national regulations for measuring instruments used for trade or regulation.

- regulations to prescribe the power for the administering authority to undertake testing for type approval, to grant approval for measuring instrument designs and issue certification of approved types of measuring instruments.

Type (Pattern) approval

The aim of type approval is to test the quality of a measuring instrument design to ensure that an instrument of that design will retain its calibration for an appropriate period of time under normal conditions of use.

The national regulations should make it an offence for a manufacturer to falsely represent that a class of measuring instrument has been approved or to falsely represent that a measuring instrument is in accordance with an approved type.

Conformity to type - of production instruments and systems

The aim of the type approval process is not only to ensure that an instrument that is tested meets the national regulations for a measuring instrument, but that all production instruments of an approved type comply with regulations.

Where production instruments fail to conform to the approved type, legal sanctions can be applied but this may not lead to desired results. For example, sanctions may put the manufacturer or importer out of business and remove the possibility of the supplier fixing the issue.

A better approach is to introduce a program of surveillance to minimise the risk of non-conformance. This could be based on the quality system of the manufacturer’s production system and include sampling of production instruments to ensure that the quality of manufacture is being maintained. Full type approval testing of sampled instruments may not be necessary in this case. It would be sufficient to test only those influence factors where the original approval testing revealed that non-conformity was most likely.

Verification

Verification aims to ensure that a measuring instrument used for legal purposes (regulation or trade) operates within the specified maximum permissible errors before it is used and throughout its lifetime.

Verification is usually carried out by trade measurement inspectors, legal metrology officers or licensed private organisations.

Market and field surveillance

Market surveillance involves monitoring the performance of measuring instruments to ensure they continue to comply with regulatory requirements. Instruments that have been relocated, repaired, or have been subjected to extreme conditions should undergo re-verification before being used.

Government inspectors or licensed verifiers usually carry out this work. Provision should also be made for random auditing and verification of measuring instruments used by traders and pre-packaged goods, which must comply with their labelled descriptions.

In cases where non-compliance is found, traders need to correct the instrument and if they fail to do this an auditor can take follow-up action.

The auditing body may consider making recommendations for traders to minimise failures of their measuring instruments.

The legal framework should include offences for any misrepresentation or false labelling and appropriate sanctions.